Inventory control is the process of ensuring the right amount of supply, raw materials, and goods stored in your company. Proper stock control helps you meet customer demand, optimize storage costs, and deliver financial elasticity. To streamline your store inventory control, you need the right process and store management software to operate your supply chain. In this article, we’ll walk you through the critical points and the best methods to control inventory for your business.

What is store inventory control?

Inventory control involves the procedures and systems to manage stock items, raw materials, and merchandise in a company. It tracks the movement of goods to calculate the stock level you should maintain to ensure a sufficient supply for sales. A good stock control system is essential to guarantee the right products at the right time to satisfy customer demand and maximize profits.

Stock controlling plays a key role in the inventory management system. It includes the following warehousing and production processes:

- Receive and store items in the right locations;

- Tracke goods during transferring between warehouses or stores;

- Record product details and movement histories;

- Keep stock, and oversee the store stock conditions;

- Fulfill customer orders with existing stock;

- Implement barcode scanners to control SKUs;

- Generate purchase orders.

The purpose of inventory controlling is to minimize holding costs and prevent overstocking and understocking. It lets you know when to replenish stock, push old items, and buy new products. In addition, well-managed inventory will free up your warehouse space and the capital tied in your stock, avoiding obsolete stock which can hurt your cash flow.

For example, if you own a cosmetics retail shop, you may keep a lot of makeup, skincare items, hair products, etc. It’s important to control the inventory like tracking the stock level, and displaying enough products on the shelves so you don’t overstock or understock. It also helps you plan better purchases and reduce maintaining costs of extensive inventory.

What are the 4 types of inventory control?

Raw materials

Raw materials are used to produce a product component or finished products. You may get raw materials from a supplier or manufacture them yourself for easy and quick access. The raw materials then become your inventory assets and shall be stored in your warehouse. Examples of raw materials are:

- Flour to produce breads for bakeries;

- Fabrics to make clothes;

- Paper and ring binders to create notebooks.

Unfinished products

Unfinished products, also called work-in-progress inventory, are the products that are being processed and will get to the market after completion. It can include goods that are being made or waiting for packaging before hitting the shelves.

An example of unfinished products can be a half-assembled car or a partially completed pair of shoes. These goods should be stored in a separate warehouse for good classification, ensuring unfinished goods are not mixed with completed goods.

Cycle inventory

Cycle inventory refers to selling a portion of store stock and swiftly replenishing them with new ones. Unlike safety stock aims to cover demand surges and dips, cycle stock is applied to cover the majority of purchases.

Small businesses mostly use cycle stock due to limited capacity for safety stock. For larger companies, safety stock is not a preferred option unless it’s required to meet increasing market demands. Usually, you should optimize your cycle stock to save money on storage, as long as you can restock them in time to avoid missing sale opportunities.

For example, you are a furniture retailer. After each day or week, you recheck your inventory and make orders to replenish the items just sold in that period. This way minimizes the storage costs, and ensures you only stock what customers look for.

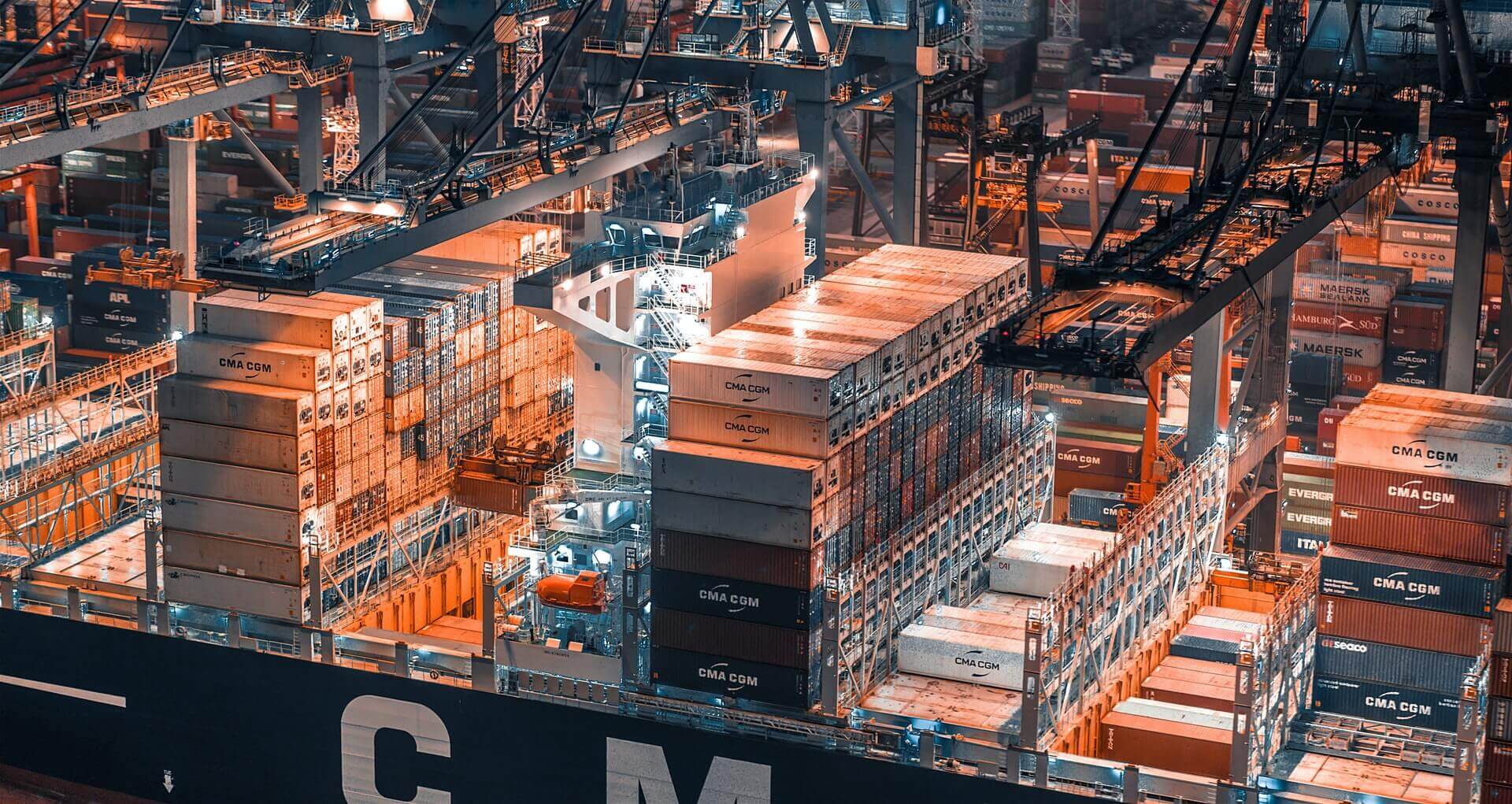

In-transit inventory

Stock that is being transferred from a vendor to your warehouse is called in-transit inventory. The items have left the vendor warehouse but haven’t reached your warehouse. It’s also known as pipeline inventory.

Although you haven’t received the stock yet, it’s still included in your inventory management and should be tracked to ensure smooth transportation. When the inventory reaches your location, the transfer of ownership takes place and you now own the goods.

Challenges of store inventory control

Inventory controlling can be complicated for retailers. Here are some of the major challenges:

Supply chain problems

Your plan of replenishing stock may not always go well. During the Covid-19 pandemic, the supply chain was disrupted due to many transportation restrictions. Such delays or cancellations of delivery can cause stockout situations and hurt your bottom line.

To tackle this problem, for example, you can reorder your best-selling products frequently to keep sufficient quantities in your warehouse. It could be your lifesaver if there are difficulties in sourcing or delivery of the products, you’ll still have enough stock to sell until the new stock arrives.

Lack of warehouse space

While delayed deliveries can cause you missed revenue, it also creates another problem. All your overdue orders may arrive at the same time and make trouble for storage space. Thus, you should have some excess space to handle this stock. When planning your warehouse space, you should design an effective layout and standardize the bins or pallets that you’ll use to keep goods.

Unpredictable customer demand

Customer demand can fluctuate and make it hard to predict. You may find yourself stocking too much or too little to satisfy the demand, and both cases can cause damage. If you don’t have enough products, your customers will buy from your competitors. In contrast, if you overstock while customers aren’t buying as much, your capital will be buried inside the dead inventories. Hence, demand forecasting based on trustworthy data is vital to match your supply with demand.

Poor communication

Miscommunication can be a trouble for stock controlling, from getting order purchases to tracking stock levels and moving products to multiple stores. Especially if you do omnichannel sales, straightforward and correct communication is essential for both internal and external collaboration to manage accurate inventory.

What are inventory control methods?

How retail stores control inventory has evolved a lot with the rising of technology. In this section, let’s explore the most popular stock control approaches that retailers have implemented.

Manual data entry

This is the traditional pen-and-paper method to record stock movement. This way only works for startups and small businesses whose inventory is simple to control. However, when your company grows bigger and expands to more SKUs, this approach can be a hindrance to scale. It is time-consuming, error-prone, and has limited capacity to analyze data efficiently.

Stock cards

Using stock cards is a slightly more complex way to monitor purchases, sales, product exchanges, and returns. It is a table recording the cost of goods sold, selling prices, and available inventory for each product.

With this method, you use individual cards for each item to track their movement across warehouses and stock rooms. You can include additional notes or remarks on the card, such as any issues or problems associated with that item.

The stock card system is only effective if you record constant and up-to-date information immediately as stock is moved. You must also keep track of unusual inventory pulls to avoid inaccurate data. This approach is a good way to trace your products, especially if you use the first-in, first-out (FIFO) inventory method.

However, stock cards also have weaknesses. It is still a lengthy process to write down thousands of cards, not to mention the risk of losing stock cards. In addition, if any problems occur, it’s hard to track back and fix the exact stock card. Using these physical cards is not optimal, since you cannot take advantage of automation with current technology.

Spreadsheets

A better method to control stocks is spreadsheets, such as Microsoft Excel or similar applications. Using spreadsheets allows you to easily and consistently update your product data. If you master Excel with coding skills, this is a good method for basic automation to acquire updated stock levels and data.

Excel can link multiple spreadsheets and connect with other systems via high-level macros or coding. With Excel, you can design customized spreadsheets for product data, inventory data, vendor information, and sales performance with relevant data fields for you.

However, using Excel spreadsheets has some drawbacks. Not everyone is competent in using Excel, so it takes time to train them on the job. Additionally, the more products you have, the heavier the files to run on computers. If you are a big retailer with a complex supply chain and sales process, you’ll need a leaner and more powerful solution to handle shop inventory. Spreadsheets are more suitable for small and medium businesses to set up basic stock control capabilities.

Software

In this digital era, software plays an important role in business management, and store inventory control is a part of it. Using an inventory control system like Magestore inventory tracking system can help you remove the obstacles of the previous methods. Here are some of the benefits that you’ll receive by adopting a digital solution:

- Save time spent on manual and repeated tasks;

- Reduce errors due to human faults;

- Streamline communication channels and get the team to be clear on the workflows;

- Prevent stock inaccuracy, losses, and theft;

- Minimize deadstock and stockouts situations.

Magestore inventory management system can be customized to your business needs, regardless of your size and industry. The system comes with POS functions and other retail management features. It is native to Magento and inherits all Magento powers and integrations. With Magestore, your stock control can reach another level of efficiency. Explore their top features below

- Generate and edit unlimited SKUs with serial numbers

- Update stock movement across locations automatically and in real time by scanning bar codes;

- Sync all data of products, sales, suppliers, and customers in a central database;

- Push low-stock alerts and create purchase orders to vendors;

- Support omnichannel sales and reflect the product availability on your public sites;

- Fulfill customer orders quickly and update the inventory level accordingly;

- Evaluate supplier performance to choose the best ones for your supply chain;

- Analyze and report on store inventory, lead-time, COGS, storage costs, best-selling and worst-selling products;

- Support accounting and inventory audit;

- Forecast inventory demand to assist you with purchasing decisions.

Magestore offers scalability and flexibility for your retail store. You can access the software from any browser and device thanks to PWA technology, unlike static Excel sheets. To go faster in this competitive retail industry, you will need a robust system like Magestore to control stocks and beyond.

Inventory control vs inventory management

Although inventory control and inventory management sound similar, they do have some differences. While inventory control deals with existing stock in a warehouse, inventory management handles the overall movement of stock across the supply chain.

Here is a comparison between the 2 processes regarding their goal, scope, key concerns, and activities:

| Inventory Control | Inventory Management | |

| Goal | Regulate the on-hand stock to ensure they are enough and in good condition | Optimize holding costs and obtain the right inventory with sufficient quantity at the right time and in the right place |

| Scope | Existing stock in storage | All raw materials and finished goods across stages of the production lifecycle |

| Key concerns |

|

|

| Activities |

|

|

Wrap up

Stock controlling is crucial to keep your retail business running smoothly. Now that you know the 4 methods of inventory control, investing in an open source inventory management system is your best option. Leveraging technology will increase your productivity and solve many challenges in your supply chain operations.