A barcode is a rectangular or square image of parallel black lines and white spaces in varying widths. Modern retailers apply barcode management to identify products quickly. That’s why it’s an excellent inventory management solution. Furthermore, COVID-19 also promotes the adoption of barcode readers as a contactless solution. According to Grandview Research, the global barcode reader market size is $6.79 billion in 2020 with a compound annual growth rate (CAGR) of 6.7% from 2021 to 2028. However, it can be challenging to understand barcode definition and how they work. Thus, this article will clarify “What is a barcode?” and how you can apply it to your business.

What is a barcode?

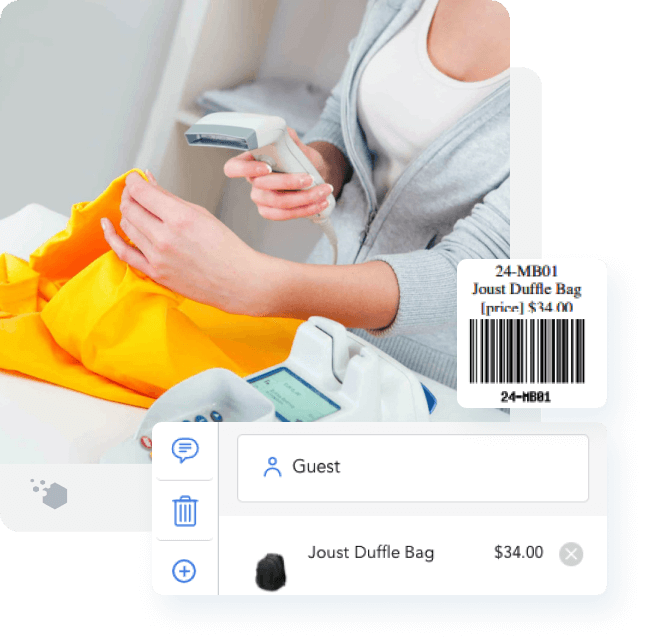

A barcode is a computer-readable representation of numbers and characters. It usually consists of parallel black and white bars of different widths that a barcode scanner can read. However, what do barcodes mean in retails? These days, you can easily see stripes like the one shown below on product packages at retail stores, convenience stores, and supermarkets. After capturing the information, barcode scanners transmit barcode numbers information in real time to the POS hardware without additional human intervention.

Thus, barcodes help retailers automate the data collection process and reduce human error when tracking inventory and processing transactions at the point of sale (POS). In addition, barcodes are essential in the purchasing process and inventory control procedures in the retailer’s warehouse. From there, you can keep track of your inventory, assist your accountant with invoices, and many more uses.

What are barcode components?

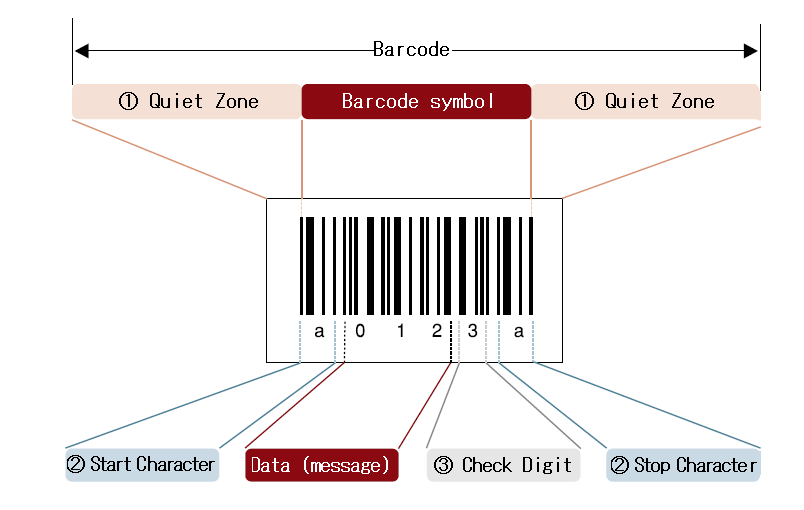

The composition of a typical barcode is standard in all countries and can be read by inventory management systems. Traditional barcodes consist of the following 3 components:

Quiet zone (margin)

A quiet zone is a blank margin located at either end of the barcode. If the quiet zone isn’t wide enough, it’ll be difficult for the scanner to read the barcode. Therefore, the minimum margin distance from the outermost bar of one symbology to the outermost bar of another symbol is 2.5 mm.

Start/Stop character

Start/Stop characters are characters that represent the start/end of the data. These characters will vary slightly depending on the barcode type.

Check digit (symbol check character)

Check digit is a digit to validate the barcode. Thanks to its symbol check character, you can check if the barcode data encoded in the barcode is correct.

How do barcodes work?

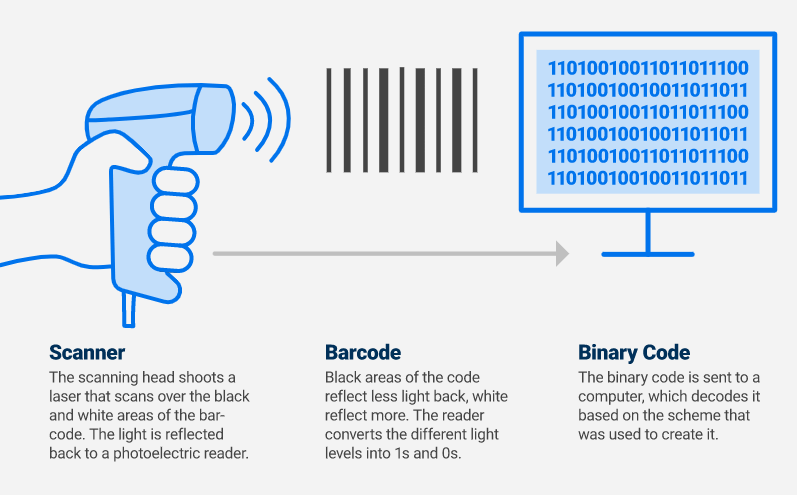

While you can see barcodes every day, have you ever wondered how they work? Here’s how barcodes work:

- First, barcode scanners will use an incandescent light bulb or laser to shine light through the barcode and then shine it into a super-sensitive light detector.

- The black lines on the barcode absorb light, and the white parts of the barcode will shine through and be reflected.

- The scanner detects the amount of light that is then converted into computer-readable data. For example, the black parts that do not reflect well are recorded as 1 and the white parts recognized by the light scanner as 0.

- Inventory management software will receive and decode this information on the system.

Now you know about the lines, but what about the identification numbers below? All barcodes will have 12 digits, usually printed underneath as a precaution for possible complications. Here’s what the barcode numbers represent:

- First number: Product type

- 5 following numbers: Manufacturer Code

- 5 following numbers on the right: Product code

- Last number: Barcode number according to a self-policing system

Two types of barcodes

There are many barcode variations, depending on the application. However, there are 2 most commonly used barcode types by retailers are 1-dimensional (1D) barcodes and 2-dimensional (2D) barcodes.

1D barcodes

1D barcodes store textual information such as product type, size, color, and ISBN (for book products). Thus, you can find 1D barcodes on top of the universal product codes (UPCs) on product packaging and use them to track the product delivery journey of 3PLs such as FedEx, UPS, and post offices worldwide.

2D barcodes

2D barcodes include more information than just text, like inventory levels, prices, and product images. However, it’s more complex than 1D barcodes, so not all barcode scanners can read 2D barcodes. For example, linear barcode scanners cannot read 2D barcodes. However, you can use image scanners or smartphones to read them.

Why are barcodes important?

Barcodes are an essential solution in speeding up the process of inventory management and sales transactions. For retailers, “What are barcodes used for?” include the following 5 benefits.

1. Less human error

When your employees use barcodes as identification numbers to process product data, it’s more accurate than manually entering data. From there, it minimizes human error.

2. Real-time data processing

Barcode has the speed of processing information and data immediately. It tells you real-time inventory levels and sales for each product in your retail store. Due to the breakneck processing speed, you get information on inventory levels and available sales in real time from barcode components.

3. Affordable deployment cost

It’s swift and straightforward to generate barcode numbers for all your products in stores and warehouses. Additionally, retailers can anticipate post-implementation savings with improved transaction speed, the accuracy of sales data, and improved inventory.

4. Better inventory management

Retailers benefit from improved accuracy and real-time data of barcode numbers. As a result, you can count cycles faster and estimate inventory turnover more accurately. Hence, you can keep less inventory and know when to restock.

5. Reduced training requirements

Your employees can easily use barcode scanners without training or complicated processes. They only need to point and click to identify and extract product information. In addition, employees will have to learn and keep a lot fewer thanks to barcodes.

Types of barcode scanners

There are 4 most popular types of barcode scanners on the market based on the technology they use.

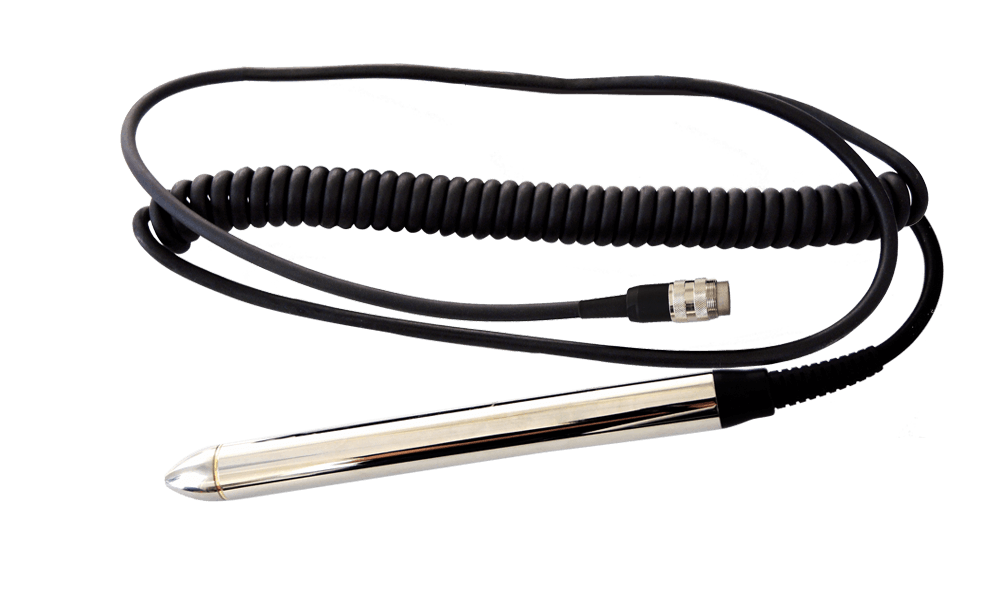

Pen barcode readers

Pen readers, or barcode wands, look like wands. This type of scanner consists of a photodiode and an LED at its end. When you scan barcodes with this pen, the LEDs illuminate the black and white bars. The light reflected from these rods varies according to their thickness and is picked up and converted into digital information. Pen readers are the least expensive type of barcode scanner.

Laser barcode scanners

Laser barcode scanners are the most common type of barcode scanner in the retail sector. They work similar to pen readers but give more accurate results. The way it works is to use a laser beam fired at an internal mirror to ensure the laser scans the barcode in a straight line. It can read a long strip from 2–8 feet away and up to 30 feet away. This type can be mounted or hand-held.

Charge Coupled Device (CCD) barcode scanners

CCD scanners or LED scanners are expensive and give accurate results because they have hundreds of tiny LEDs arranged in a row. Thus, it shoots directly at the barcode, and the voltage of the ambient light is measured. As a result, they are widespread in POS applications. However, the CCD cannot read codes that are longer than the face of its scanner, so you need to keep them within 1-3 inches of the barcode.

Imager/Camera-based barcode scanner

The camera-based barcode scanner looks more like a video camera than a scanner. It includes an internal video camera and takes a barcode picture, which is then analyzed using sophisticated digital decoding techniques instead of a laser to shoot light at the code. So you can read the barcode no matter how you place the scanner in front of it. It’ll speed up scanning many times and can read 2D barcodes.

Related questions

After knowing “What is a barcode?”, there may be some questions that you want to clarify to understand this concept better. Here are the 3 most prominent bonus questions from our list.

Who invented the barcode?

Norman Joseph Woodland invented barcode numbers when drawing a series of lines in the sand to represent the Bernard Silver code and the Morse code. He then developed the barcode concept and got a patent in 1966. NCR was the first company in the world to use a commercial barcode scanner to read barcode symbols. And a pack of Wrigley gum was the first item ever to be barcoded at a Marsh supermarket in Troy, Ohio, the home of the NCR.

How is a barcode made?

A barcode is made of black and white bars, also known as barcode components, representing different text characters that follow a pre-established algorithm for that barcode. The barcode scanner will read this black and white bar pattern and convert them into information that your point of sale system can understand.

Can 2 products have the same barcode?

Yes, 2 products can have the same barcode. For example, even if you have a batch of 20 T-shirts, they may all have one barcode number. The reason is that you don’t need 20 unique barcodes for a shirt type. Retail stores only need individual barcodes for each product, not individual items, to manage inventory and track sales.

Final thoughts

Every product from cereal packs to library books has a barcode. Although they seem simple, these black and white stripes are essential for the smooth execution of many retail activities. For example, barcode numbers are powerful inventory management tools and provide consistent visibility into your inventory at any given time. However, you should have the right inventory control processes in place, along with the right supporting software, to generate real-time and well-informed inventory reports to plan your business from these identification numbers.