What is inventory carrying cost?

Inventory carrying cost is the expense of keeping items in stock before you use them to fulfill orders and turn into liquid capital. This cost is typically expressed as a percentage of the total value of inventory.

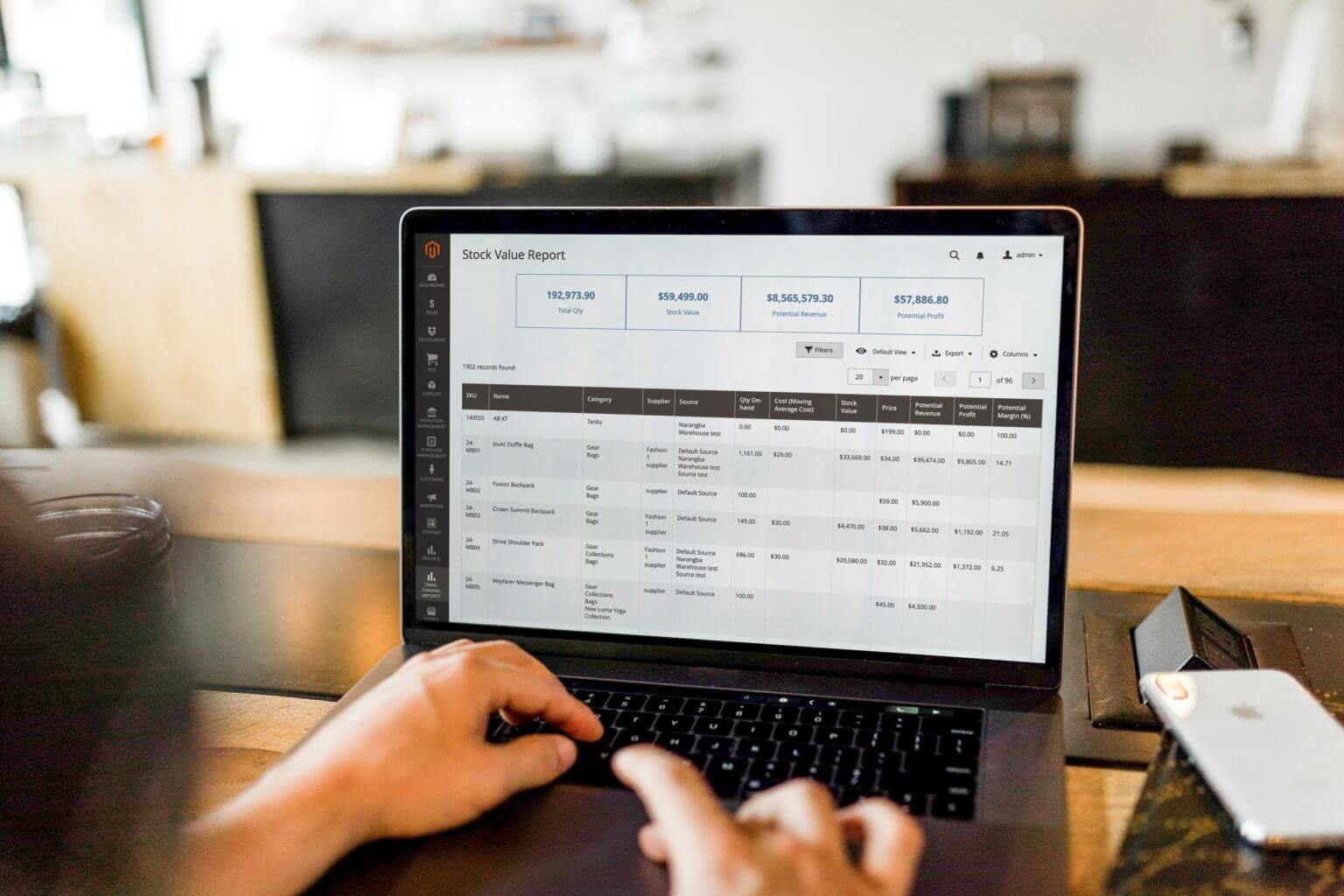

As carrying costs make up a significant expense in the supply chain, they directly impact the cost of goods sold and your bottom line. If you use an inventory management software to track the carry cost of inventory over time, you’ll have a better picture to make informed decisions on:

- Optimal inventory levels

- Scheduling pre-ordered shipments

- Long-term inventory planning

In addition, monitoring this cost ensures that you don’t suffer severe losses from holding inventory for a long time.

Components of inventory holding cost

Inventory carrying cost consists of 4 categories:

- Capital costs: Cost of purchasing inventory or raw material items and associated finance charges such as interest and loan maintenance fees. This cost type accounts for the highest proportion, about 25%, of total inventory value.

- Inventory service costs: Cost to keep goods in the warehouse, including fees for inventory management software, hardware investments, insurance, and taxes.

- Inventory risk costs: The risks of unsold inventory due to obsolescence, expiration or damage, or product shrinkage due to theft or incorrect record keeping. In addition, if you store items for too long in the inventory, their value may drop compared to their original value.

- Inventory storage space costs: Cost to purchase or rent warehouse space, move items in and out of the warehouse, and pay for physical security, climate control, and utility management. If you own your warehouse, these costs are fixed and predictable. If you utilize third-party logistics providers (3PL), the cost of outsourcing warehousing and shipping logistics can fluctuate depending on volume and usage.

In addition to the above 4 types of costs, there are opportunity costs, which are investments and improvements that you fail to make because your assets are tied up in inventory. While you can easily quantify costs like rent storage space, you also need to consider intangible costs that are difficult to measure, like this opportunity cost.

With a clear understanding of carrying cost definition and components, you can decide when to make the necessary adjustments to your inventory control procedures. Now, let’s see how to calculate it.

How to calculate inventory carrying cost

Inventory carrying cost formula

Inventory carrying cost (ICC) = Inventory holding cost / total inventory value x 100

In which:

- ICC = capital costs + service costs + risk costs + storage space costs

- Total inventory value = inventory costs x stock of available items

For example, a bicycle retailer has a total inventory value of $100,000. Their inventory holding amount is $25,000. Then:

ICC (%) = Inventory holding sum / Total value of inventory x 100

= 25,000 / 100,000 x 100

= 0.25 x 100

= 25%

So this retailer’s carrying cost is 25% of their total inventory value.

Carrying costs help you compare your profits with those incurred due to the inventory you hold. So, always keep in mind that your average carry cost of inventory should be within 15–30% of your total inventory value.

What is the monthly cost of inventory?

Monthly carrying costs can include the mortgage payment, real estate taxes, operating expenses, lender-required reserves, interior, and exterior maintenance, sewer, water, trash pick-up, recycling, cable TV, heat, and air conditioners.

Is carrying cost an expense?

Yes, carrying costs is an expense. However, it rarely appears as an expense account or a line in your income statement. Instead, the carry cost of inventory appears on the income statement under several named accounts, such as warehouse insurance expenses.

Inventory carrying cost definition in accounting is one of the most significant expenses for retail, so it’s essential to accurately calculate the inventory holding cost and the value of those products. In addition, it’s easier to measure profit by item once you deduct that cost.

How to reduce inventory carrying expense

Below are 5 ways to limit inventory expenses to optimize your inventory performance.

1. Get the right replenishment

The COVID-19 pandemic shows the importance of a just-in-time inventory strategy. However, some retailers still often keep too many of the wrong items at the wrong time. In addition, high carrying costs may mean you’re holding more inventory than you need. As a result, you can adjust the ordering frequency with your distributors or manufacturers based on actual demand to reduce inventory carrying costs.

Tips:

While it takes time to experiment and achieve the right inventory balance, it’s well worth it as inventory optimization significantly reduces the costs of inventory. You can consider a modern inventory management software to:

- Track a wide range of inventory key performance indicators (KPIs)

- Evaluate each SKU if it deserves a spot in your retail store or warehouse

- Decide on the appropriate inventory to keep

- Alert when it’s time to re-order and suggest how many to buy

- Make an accurate inventory forecasting

2. Accelerate inventory turnover time

Another effective way to reduce the carry cost of inventory is to increase the percentage of goods sold. It means reducing the time inventory items stay on your shelves.

Tips:

You can reduce obsolete inventory by offloading inventory while it still has value. If you don’t decide in time, you may end up paying to dispose of or throw them away.

- Review all product’s performance every month to see if they sell at the expected rate.

- Adjust if sales are lower or higher than expected. When you’re moving through inventory too slowly, promotions can help with that.

- Give it away, sell it to a liquidator, or donate to a charity if a deep discount can’t help.

Again, the ability to interpret specific business trends and market forecasts will improve your inventory turnover ratio. Therefore, you don’t have to keep obsolete inventory in the warehouse and reduce costs and space by checking inventory regularly.

3. Redesign your warehouse

As mentioned in the previous part, most retailers are often not making the most of their space. However, they might be surprised to know how efficient warehouse inventory management can significantly reduce inventory holding costs.

Tips:

A warehouse redesign can reduce the chance of existing inventory going unnoticed, thereby reducing obsolescence, depreciation, tax, and insurance costs. Warehouse modifications may include:

- Using containers for more efficient storage

- Adding a stand to increase vertical space

- Placing popular items in a central location

If you use 3PL logistics providers, you can review your warehouse layout or how you store products of different shapes and sizes to reduce storage costs. From there, you can move to a smaller warehouse, another way to cut inventory carrying expenses.

Also, you can rearrange your warehouse to increase your employees’ productivity. For example, experiment with different picking methods, store the most popular items near packing stations, and apply automation. Advanced inventory management software often features mapping the most efficient picking routes and simplifying the order fulfillment process.

4. Implement an automated inventory management system

Paper records and Excel spreadsheets can make your inventory reports inaccurate and impossible to update in real-time. Thus, technology plays a central role in an efficient supply chain with accurate production and inventory planning based on:

- Accurate data

- Ability to effectively analyze, interpret that data, and detect trends in numbers

Tips:

One decisive step you can take to reduce your inventory carrying cost is investing in inventory management software. This solution offers a multitude of ways to optimize inventory levels and cut your carrying costs. Choose an inventory management system that updates in real-time because it can:

- Establish consistent receiving, shipping, and fulfillment processes

- Show and retrieve the status of all customer orders and outstanding orders

- Track metrics like inventory and sales volume

- Provide an accurate real-time picture of inventory levels

- Increase inventory visibility to make intelligent decisions

- Suggest ideal inventory balance

A warehouse management solution can help you achieve greater efficiency in the cost of inventory. From there, you can focus your valuable time on your new business plan, also reducing opportunity costs.

Read more: Guide for SMEs inventory management [INFOGRAPHIC]

5. Negotiate with suppliers

The final method to minimize inventory carrying expenses is to negotiate with your suppliers. It ensures that you don’t incur much expense and risk before a customer buys these items.

Tips:

Based on inventory forecasting, you can purchase more strategically and have the basis to negotiate lower purchasing prices with suppliers to reduce the total inventory value.

- Structure the contract with suppliers so they’re responsible for theft damage or administrative costs when the goods haven’t arrived at your warehouse

- Specify a maximum inventory retention period in the agreement

- Charge for each day after that period to offset the carry cost of inventory

Conclusion

When it comes to the inventory carrying cost, you should regularly calculate it. Thus, you can identify and eliminate inventory inefficiencies and establish benchmarks to guide future business decisions. Then, businesses can work towards leaner operations to bring down your cost of inventory.

Digitization, data insights, and inventory forecasting are the tools that will make this possible. Instead of tracking inventory by hand and conducting manual cycle counts, consider the benefits of inventory management software.

If you’re a Magento merchant looking for an inventory management solution, you can start with a free consultation with us. Together we’ll build a solution that fits your unique business requirements.

Can someone help explain… Inventory Carrying Cost supposedly helps you identify when you have too much inventory / holding it too long. However, the figure drops as you increase the inventory you have on hand. How is this helpful? Is it intended to work in tandem with turnover rate?

Example

Holding sum / inventory value = holding cost

Scenario A

$10,000 / $20,000 = 50% (bad)

Scenario B (more stagnant inventory)

$10,000 / $40,000 = 25% (good)

What gives?