Add-on available

Serial numbers are unique numbers assigned to individual products for identification purposes. Along with barcodes, serial numbers help retailers manage their inventory and easily track stock movement.

In this article, we’ll explore 3 benefits of serial number tracking and the process to track serial number in a retail business.

3 inventory management issues serial number can solve

Serial numbers are often used for products such as electronics, automobiles, or jewelry — expensive items and items that require after-sales services. Here are 3 common issues that serialized inventory can solve for you:

Handling support and warranty issues

When customers request a return or warranty, your staff will need to track serial number to confirm that the product is yours. In addition, they need to check the warranty status and period. This means they’ll require data about the original transaction, such as the item’s unique code and sold date.

In some businesses, your sales associates will do both sales and aftersales. If they don’t have the relevant information to handle the request, they won’t be able to support the customer in time. This can affect the customer’s experience with your brand and your reputation.

On the other hand, there’s also the risk of giving support to unwarranted products or products past the warranty period, costing your business additional time and resources.

Tracking suppliers

When retailers work with many suppliers that provide the same products, they have to be able to distinguish between them. Serialized inventory helps merchants control the quality of the products they’re selling and make sure they get the best deals when purchasing.

On the other hand, sometimes you’ll want to send a defect item back to the supplier for repair. Without the proper procurement information, communications between you and the supplier can take a long time. The customer who’s waiting for their product to be fixed will also be unhappy with the support time.

Managing consignment inventory

Besides selling their own items, some retailers also sell products on consignment. In this sales model, suppliers only need to pay after you’ve sold the goods to consumers.

If you manage stock with SKUs, an SKU can be both an item purchased by the business owner and a consignment good. As a result, it’s necessary to track the sales and inventory of consignment products separately from those of other products. Serialized inventory is essential to reconcile finance with the suppliers.

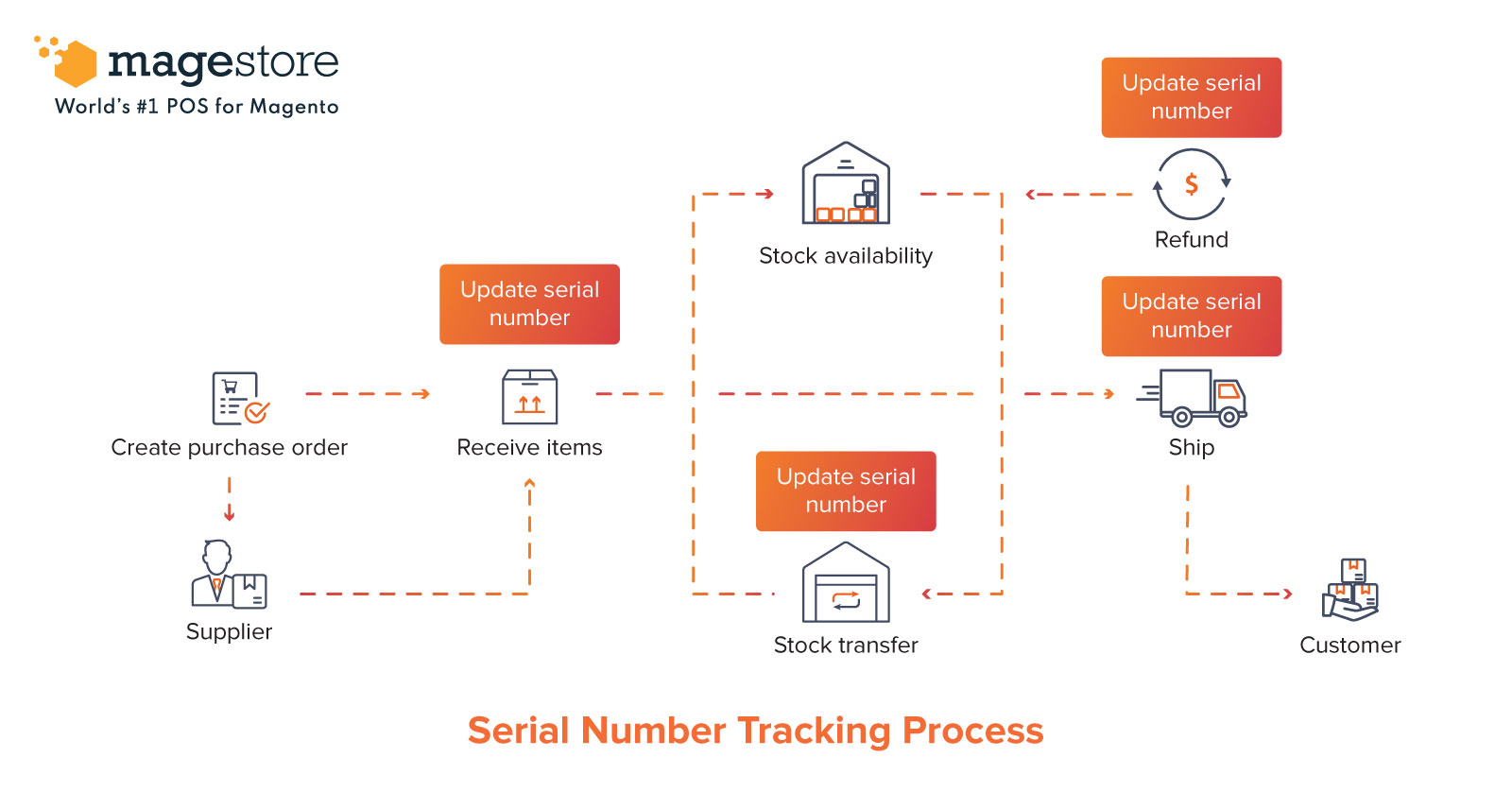

How to track serial number in a retail business

Let’s look at the process to track serial number from reception to sales and after-sales.

Purchasing

When purchasing staff receive items from suppliers, they can scan or manually add the serial number to the receiving slip.

If you’re allocating items from a central warehouse to another warehouse or store, your purchasing staff can input the right serial numbers in the inventory transfer form.

Sales in offline store

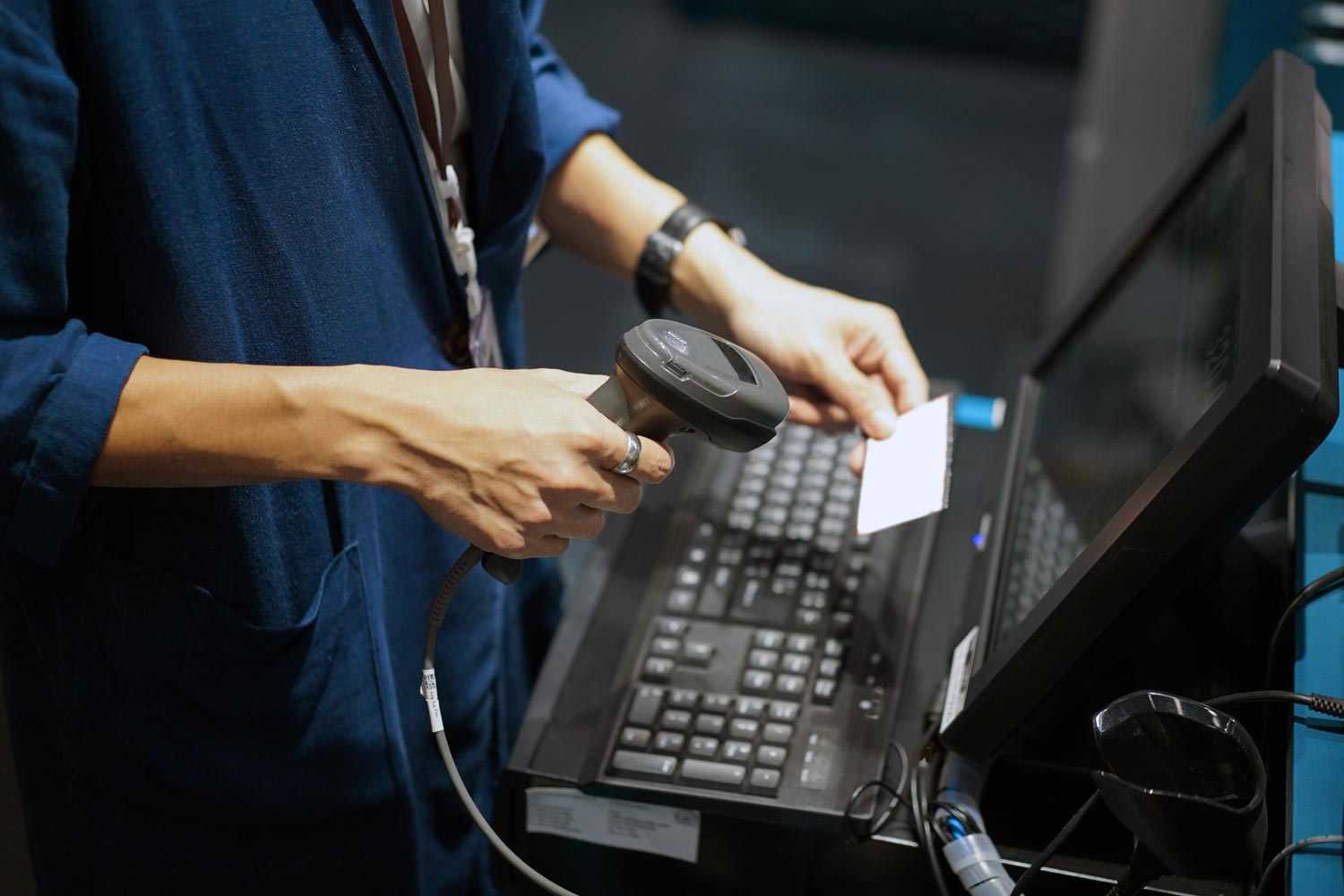

During in-store checkout, the cashier will need to scan the item’s serial number or input it manually into your POS system.

You should attract the serial numbers directly to each item to make the checkout process more convenient. If your POS system can display the serial number for each item in the shopping cart, it helps the staff see that the system has recorded the serial numbers successfully.

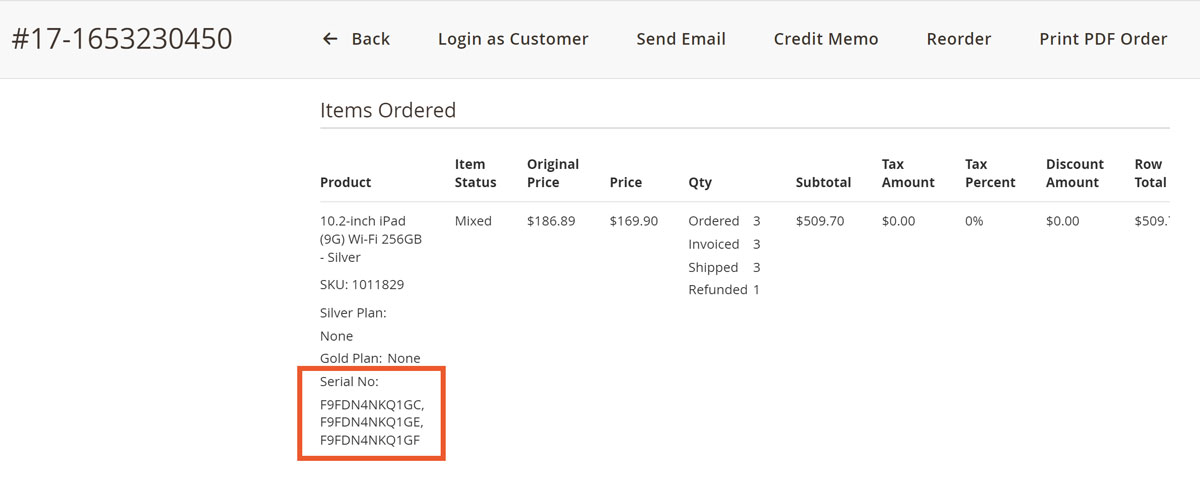

These serial numbers are saved to order history, sales receipts, and customer invoices. Your staff can check one of these documents to reference product information for support.

Additionally, when a customer requests a return, the staff should check the item’s serial number and create a credit memo with the recorded number.

Inventory management

When your staff scans a serial number, your system should show which warehouse your item is at and a detailed description.

After an order is complete, the system will create a shipment form with the serial number. Simultaneously, the stock of the purchased item decreases. In contrast, your inventory will increase after any procurement activities.

If retailers want to transfer products across multiple warehouses, you have to identify the serial numbers during allocation. For example, when your warehousing staff moves an item with the serial number of AX1000 from store A to store B, they should record the transferred number. Then item AX1000 should be available at store B and unavailable in store A.

Your inventory management system should help you track all stock movement activities of each serial number.

How to track serial number on Magento

While serial number is not a feature in Magento core, with Magestore solution, retailers can track serial number during operations for complete traceability.

Set up serial number

When you create a new product in Magento backend, you can configure the product to require serial number. If you enable this for the product, the system will request your staff to input the serial number during operations such as customer checkout.

Generate serial number in Magento backend

Some merchants want to manage serial number right on Magento, while others use a third-party ERP system. Magestore can set up a complete serial number workflow for you on Magento, or help you integrate Magento with another ERP system to track serial number.

Here are some processes you can execute in your Magento backend with Magestore solution:

- Generate serial number for your product:

- Import a list of serial numbers via CSV file:

- Print serial numbers based on a template:

- Check the serial number status and product information:

Record serial number at sale

After checkout, the POS will display the shipment page.

Your staff can fill in or scan the serial numbers for items with the Serial Number Required attribute. The POS will increase the Qty to Ship by 1 for each serial number.

In case you need to ship the products later from another location, your staff can create another shipment and scan the serial numbers for the rest of the items.

Explore solution: Track & manage items in real time for better inventory visibility

The serial number will be recorded into the order detail on POS and backend.

Your staff can also record serial number during the RMA process.

Record serial number during purchasing process

To connect procurement, inventory, and sales processes, Magento merchants can also track serial number when you purchase products from your suppliers.

You can add serial number when receiving products:

Your staff can also scan serial number to find products to return to the supplier:

Serial number tracking solution for merchants

Serialized inventory helps merchants track the movement of items from suppliers to customers. Thanks to this, retailers will have accurate inventory information across their supply chain, reducing operation costs and increase sales opportunities.

However, keeping track of serial numbers using a manual paper system or Excel files can be painful and time-consuming.

Retailers with a brick and mortar store should implement a POS system that allows them to keep track of serial number across all operations. Now they can spend less effort on tracing item data and more time to provide exemplary customer service in other parts of the stores.

If you’re a Magento merchant looking to track serial numbers in your inventory, we can help build a customized solution for you. Talk to one of our experts today and make inventory management easier for your business.