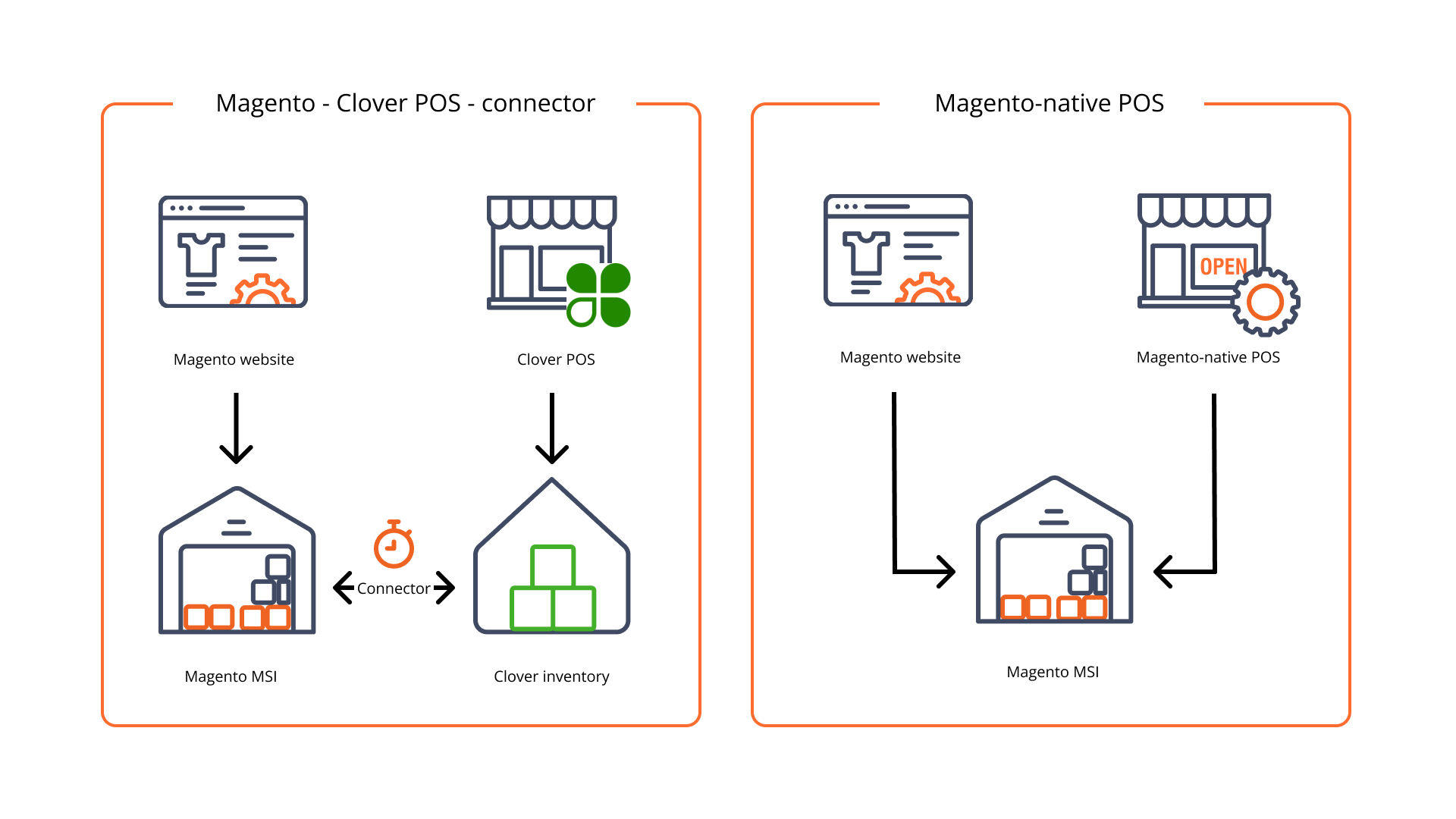

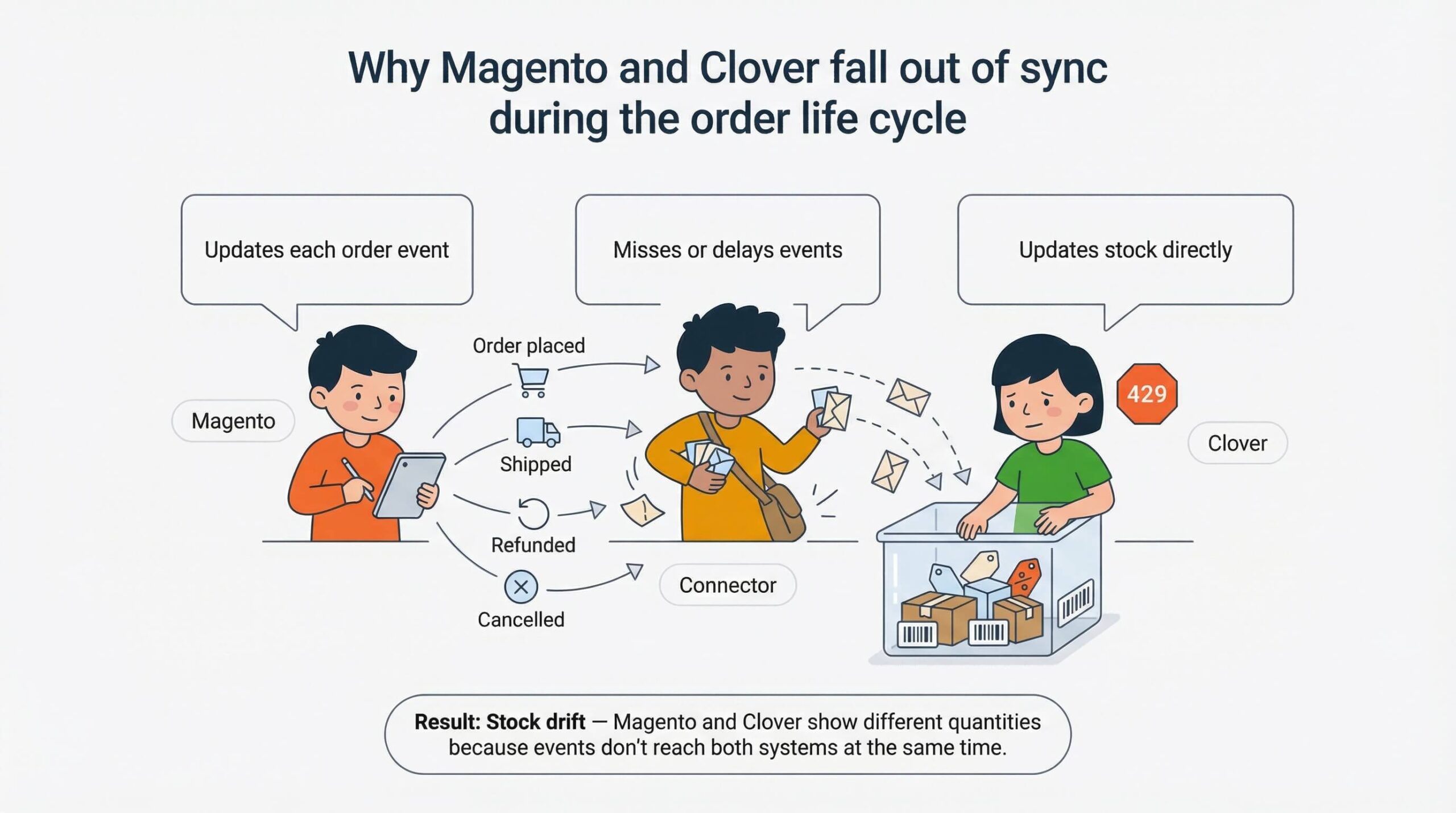

Stock drifts in a Magento–Clover–connector setup because each system updates inventory in its own way and at its own time.

Magento’s Multi-Source Inventory (MSI) uses reservations to control what can be sold, while Clover keeps item counts in its own database. When the connector updates too late, misses an event, or maps data differently, Magento’s salable quantity and Clover’s item stock stop matching. This gap grows fast if you have more than one location.

If you correct negative salable quantities, phantom stock, or Magento–Clover mismatches every week, the issue is not a simple delay. It’s a deeper design problem in the connector setup.

To choose your next step—tuning the connector or moving toward a Magento-native POS—you need to understand the three patterns in Magento MSI, Clover, and the connector that create stock drift.

Different update speeds, different stock counts

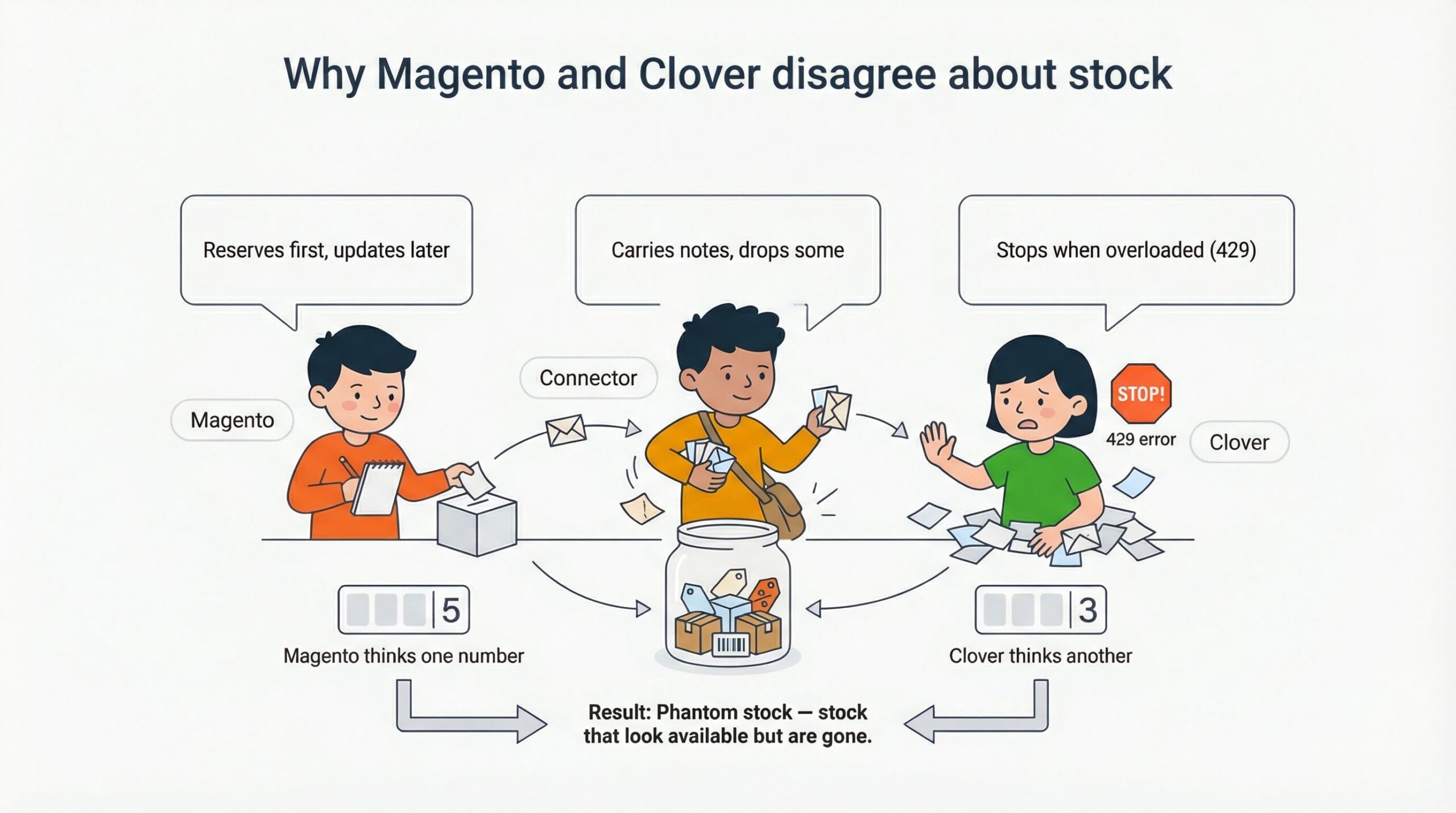

Magento and Clover do not run on the same timing.

Magento creates a reservation for each order and updates stock in the background, not at the exact moment the order is placed. (Source: Inventory Management API reference)

Clover works differently. It enforces strict API rate limits—50 requests per second per app and 16 per token. If a connector sends more than that, Clover returns 429 “too many requests” errors. (Source: Work with API usage and rate limits)

Polling connectors make the gap worse.

Each retry slows things down and adds to the queue. This widens the delay between Magento’s updates and Clover’s stock changes. Even Clover warns against heavy polling in its own docs: (Source: Best practices to avoid 429 HTTP error messages)

“Use Webhooks to avoid constant polling for updates.”

Adding a connector to the mix worsens the situation.

A Magento–Clover connector like Commercium may sync some changes right away, but other updates run every 5–10 minutes. If the connector batches or skips events, Magento keeps old reservation data until the next sync. Clover moves forward, Magento stays behind, and drift appears even though both systems believe they are correct.

For retailers, these delays create “phantom inventory”—items that seem available online but are already sold or reserved. Every minute of delay raises the chances of overselling and adds more manual reconciliation work.

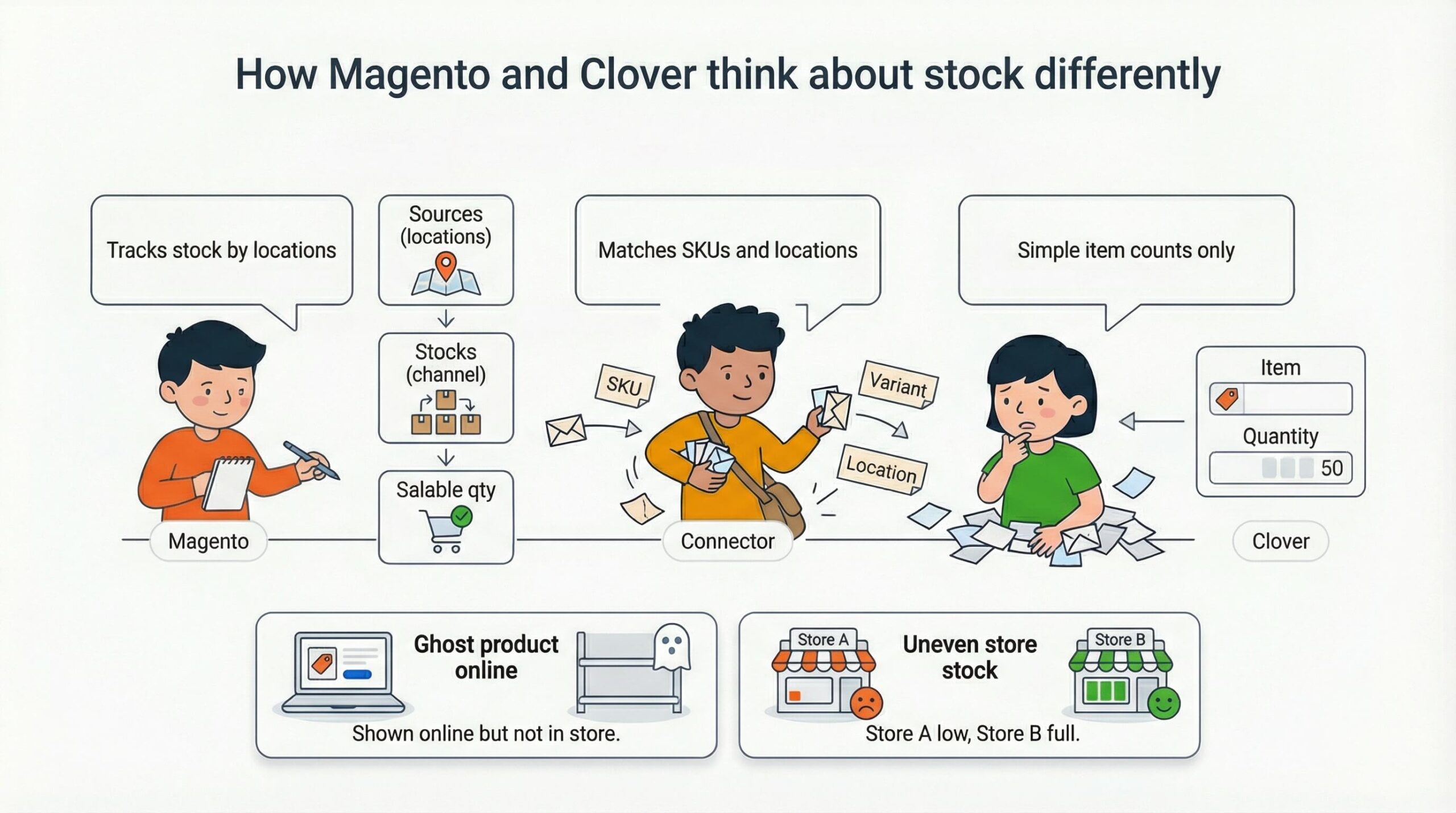

Even perfect timing cannot fix the deeper issue. Magento and Clover track inventory in different ways, so the connector must translate between them without losing important details.

How different stock models lead to mismatches

Magento’s Inventory Management uses sources to track stock at each location and stocks to group those locations for a sales channel. It then calculates one salable quantity so the website knows how much you can sell. (Source: Introduction to Inventory Management)

Clover takes a simpler path. It tracks items and their stock counts in its app and APIs. It does not use sources, stocks, or salable quantity the way Magento does. (Source: Manage items and item groups)

Because these models do not match, the connector must translate every SKU, variant, and location between the two systems. When any part of that mapping is wrong, the connector can send the wrong update, skip an update, or create a duplicate item.

This causes real problems in stores. A SKU added in Clover but not mapped in Magento can turn into a “ghost” product online or leave you with empty shelves in one system and “in stock” in the other.

The risk is higher in multi-location setups. If the connector updates the wrong Magento source or Clover location, one store can look low on stock while another looks full.

A Magento-native POS avoids these issues because it follows Magento’s source and stock structure by default. You map items once during migration, and daily sales and returns no longer depend on fragile connector rules.

*Our experts will walk you through how a Magento-native POS removes mapping errors.

Even strong mappings cannot protect you from the next issue: inventory still changes during each order event, and any event the connector misses will push the two systems apart again.

Missed order events, growing stock problems

Magento adjusts reservations at each major order event.

When an order is placed, shipped, refunded, or cancelled, Multi-Source Inventory (MSI) updates the salable quantity so stock stays correct. It also includes CLI tools to fix gaps when events don’t line up. (Source: Inventory Management CLI reference)

Clover updates item stock on its own path.

Its APIs let the system change stock directly, with no link to Magento. If the connector misses or delays a Magento event, Clover moves ahead while Magento waits for a reservation update that never arrives. The two systems drift even though both think their numbers are right. (Source: Manage items and item groups, com.clover.sdk.v3.inventory.ItemStock Class Reference)

These gaps build up over time. Missed refunds, skipped cancellations, partial shipments, or admin edits can stack into negative stock, oversells, or location-level mismatches, even when both systems behave as designed.

For teams, this means extra work. Staff spend hours running CLI commands, checking logs, and counting stock by hand just to regain a clear view of inventory.

Customers feel the results too. They run into cancelled orders, delayed shipments, or “in stock” messages that turn out to be wrong.

A setup where the POS and Magento follow the same life cycle removes these slow, hidden issues. With no connector replaying events, Magento updates in real time with each sale.

With all three drift patterns clear, you can now use them to test your setup and decide when to fix configurations—and when to consider a Magento-native POS.

How to tell if fixing the connector is enough—or if it’s time to switch POS

- Log your drift: Tag recent issues—oversells, negative salable quantity, Magento–Clover mismatches—and group them by timing, mapping, or missed events.

- Audit mappings: Check SKU, variant, source/location, and unit-of-measure mappings across Magento MSI, Clover, and the connector. Fix any one-way or unclear links.

- Trace the life cycle: For a few orders, map how placement, shipment, refunds, and cancellations move through each system. Note where the connector fails to pass an event.

- Measure reconciliation load: Track how often your team runs CLI fixes, adjusts stock by hand, or counts inventory to restore accuracy. Use this to judge whether tuning is enough.

- Define the inventory brain: Decide which system—Magento MSI or another—owns the official stock count. Avoid letting Magento and Clover both act as masters.

- Evaluate Magento-native POS options: Shortlist POS systems that are Magento-native and write straight into MSI. Compare them against your current drift cases.

- Plan the migration path: If you choose a Magento-native POS, build a phased rollout with a stock snapshot, clean SKU/location mapping, and a controlled cut-over as Clover steps back from inventory authority.

*Our experts will assess your setup and show how Magestore POS fixes your stock issues.

Myths that mislead merchants about Magento–Clover stock drift

Myth 1: “Our connector is real-time. That should eliminate drift.”

Even “near real-time” connectors can still drift. They may skip or misread events like refunds, partial shipments, or cancellations, or post stock changes to the wrong source or location. Adobe’s own guidance shows that reservation issues come from missing initial or compensating reservations, not only from timing delays.

That’s why reducing the number of systems that must replay these events—and letting the POS write straight to Magento—cuts down the silent misses that cause drift.

Myth 2: “We can just disable MSI and go back to simple quantity.”

Turning off Inventory Management removes reservations and multi-source support. You also lose Magento’s built-in protection against overselling and its ability to manage stock across many locations. Any choice to disable MSI is a major architecture change and needs direct expert review.

Myth 3: “Clover already tracks inventory. Magento can be read-only.”

If Magento becomes read-only, its salable quantity no longer reflects what Clover sells or refunds. This creates storefront promises that no longer match store reality, especially in multi-location setups. In practice, you give up Magento’s guardrails against overselling.

Read more:

Final thoughts

If you keep matching Magento’s salable quantity with Clover’s counts, it is not random. The drift comes from three things working together: how Magento uses reservations, how each system models inventory, and which order events the connector misses.

You can tighten mappings and add more checks, and that will help for a while. But as long as more than one system tries to control stock, the drift will keep coming back.

The simplest way to stop fighting these patterns is to stop stock drift by switching to a Magento-native POS that writes straight into Magento Inventory Management instead of going through a connector.

FAQ

1. Can we tune the connector to eliminate drifts?

Tuning can help, but only to a point. Adding webhooks or filters reduces noise, yet these tweaks can’t overcome hard limits in Clover’s API or Magento’s asynchronous Multi-Source Inventory (MSI) process.

Even the best-optimized connector still waits for two systems to finish their own cycles. When rate limits or background jobs fall behind, drift reappears.

2. MSI is the problem. Can we just fix MSI?

MSI isn’t broken—it’s event-driven by design. Every order, shipment, or refund triggers a reservation event that keeps Magento’s stock totals balanced over time. Drift occurs only when those events fail to process, queues stall, or consumers stop running.

Treating MSI as faulty diverts attention from the real issue: integration fragility.

3. Can a connector between Magento and Clover POS use webhooks?

Yes — but only partly, and with limits.

Clover’s Developer API supports webhooks for events such as orders, payments, and inventory changes. A connector can subscribe to those events to trigger updates in Magento instead of waiting for a scheduled sync. That helps reduce delay but doesn’t make the system truly real time.

Magento’s Multi-Source Inventory (MSI) still processes updates asynchronously, and Clover’s webhook service itself obeys rate limits and retry rules. When either side slows down, the queue builds up again and drift returns.

Magento also can’t natively listen to external webhooks without a custom listener or middleware. So even “webhook-driven” connectors end up relaying events through another queue before Magento applies them.

In short: webhooks help but don’t fix the drift problem. Only a Magento-native POS, which writes orders and inventory directly into Magento, removes the need for connectors and their sync windows altogether.